Episode Transcript

According to the International Energy Agency, bioenergy provides around 10% of the world’s total primary energy supply. In 2018 alone, 154 billion liters of biofuel were produced worldwide. Additionally, production of biofuels is expected to increase 25% by 2024, as it becomes more competitive in energy markets in Brazil, the US and China. But what is bioenergy? How helpful can it be in the global effort to decarbonize, and how much will it cost to scale up production to help accelerate the transition away from fossil fuels? We spoke with Jerry Tuscan, CEO for the Center for Bioenergy Innovation, and Matt Langholtz, natural resource economist from the Bioenergy Group at Oak Ridge National Laboratory. So, what is a biofuel and where does it come from?

Jerry Tuskan:

A biofuel is a liquid fuel derived from biomass, and biomass is just dried plant matter. So imagine taking wood chips or chopped up grass and converting it using bacteria into a liquid transportation fuel. And that becomes a biofuel. By using biofuels, we can displace that petroleum and reduce the amount of carbon dioxide emissions in the transportation sector here in US. So it’s a means of reducing the amount of carbon through capture of growing biomass, Poplar, or switchgrass or other forms of plant biomass, harvesting the above-ground portion and converting that into fuel and leaving the perennial root systems intact in the soil so that that carbon remains fixed in the soil.

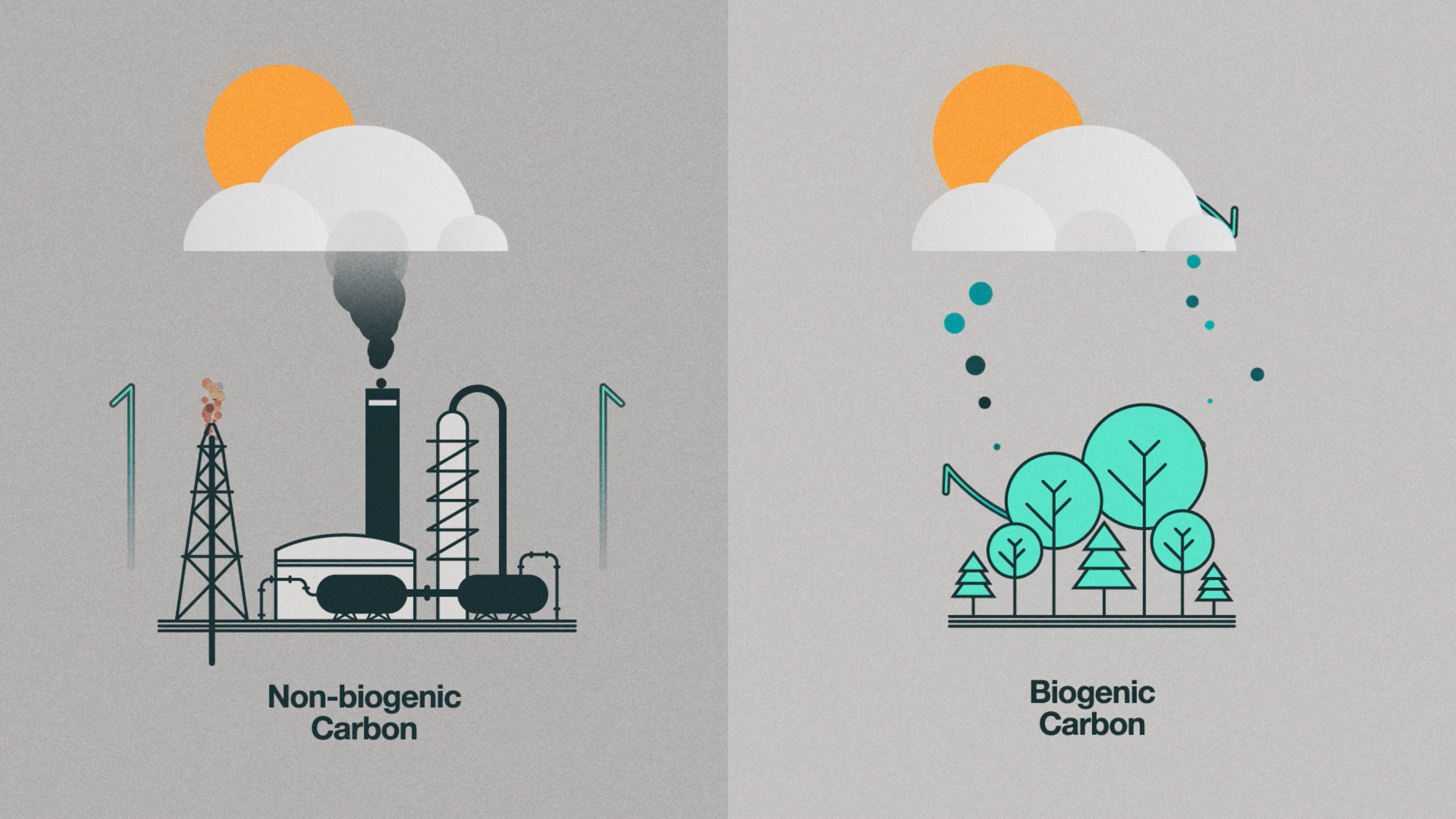

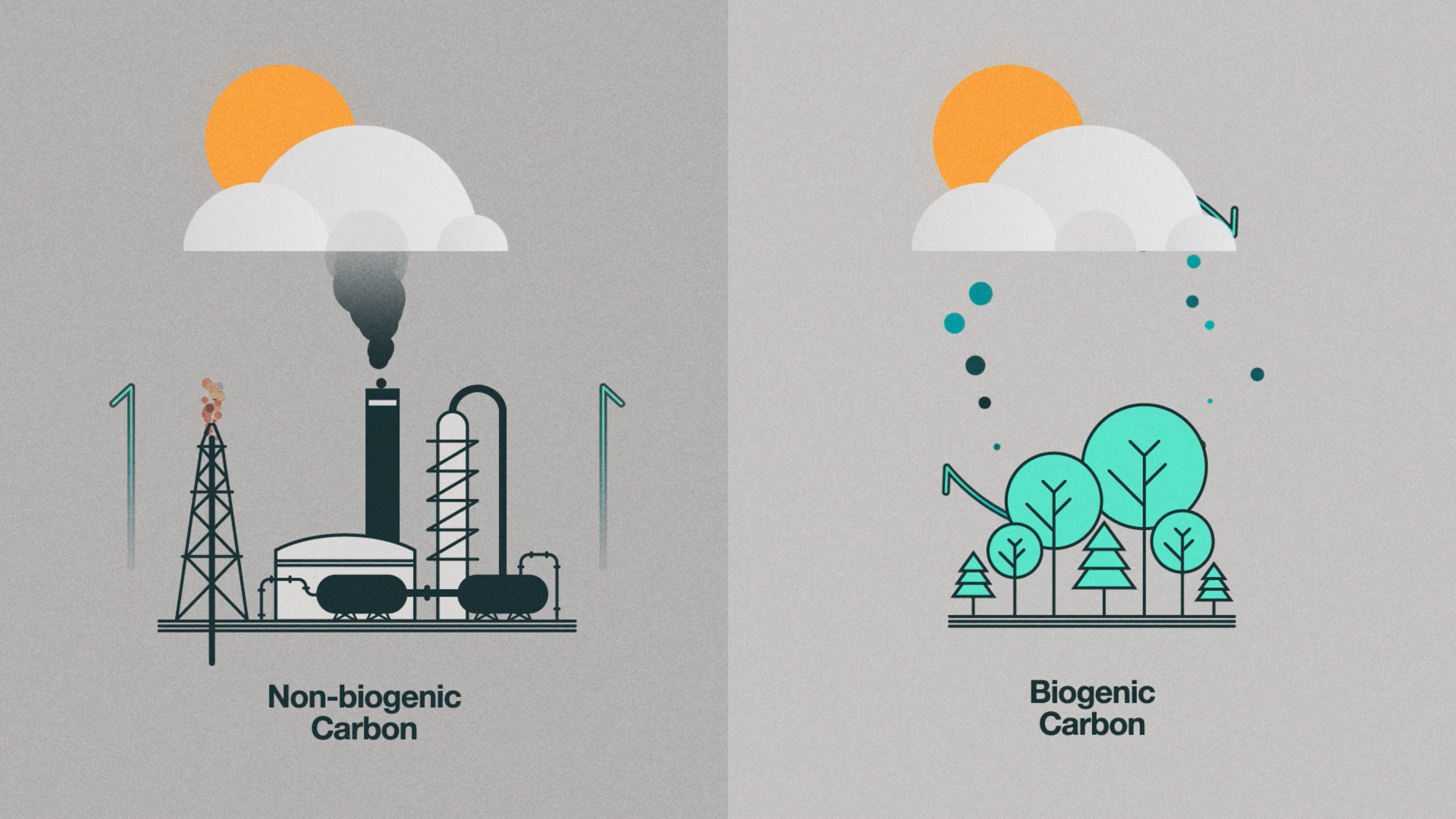

This is the difference between CO2 emitted from fossil fuels and CO2 emitted from bioenergy. When burning fossil fuels, carbon is released into the atmosphere after being locked underground for millions of years, thus increasing the total amount of carbon in the biosphere and atmosphere. Biofuels, on the other hand, are part of a closed-loop system in the carbon cycle, and are thus considered to be net-neutral in terms of carbon dioxide emissions. Carbon is captured by bioenergy feedstocks, which are turned into fuels, combusted, and the cycle repeats. And if you add carbon capture and storage technology, which captures the carbon at the point of combustion and then stores it underground, biofuels become net-negative.

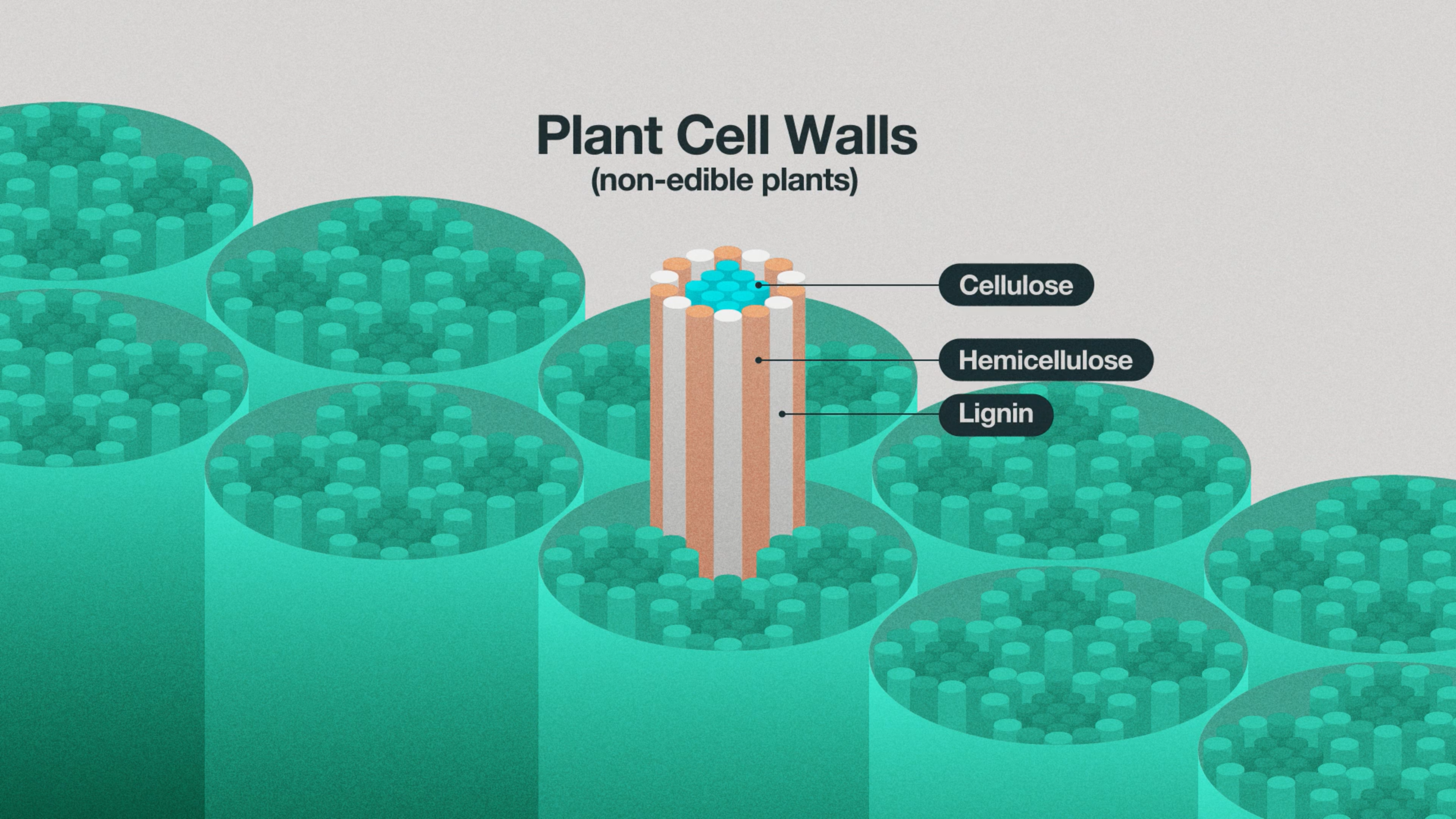

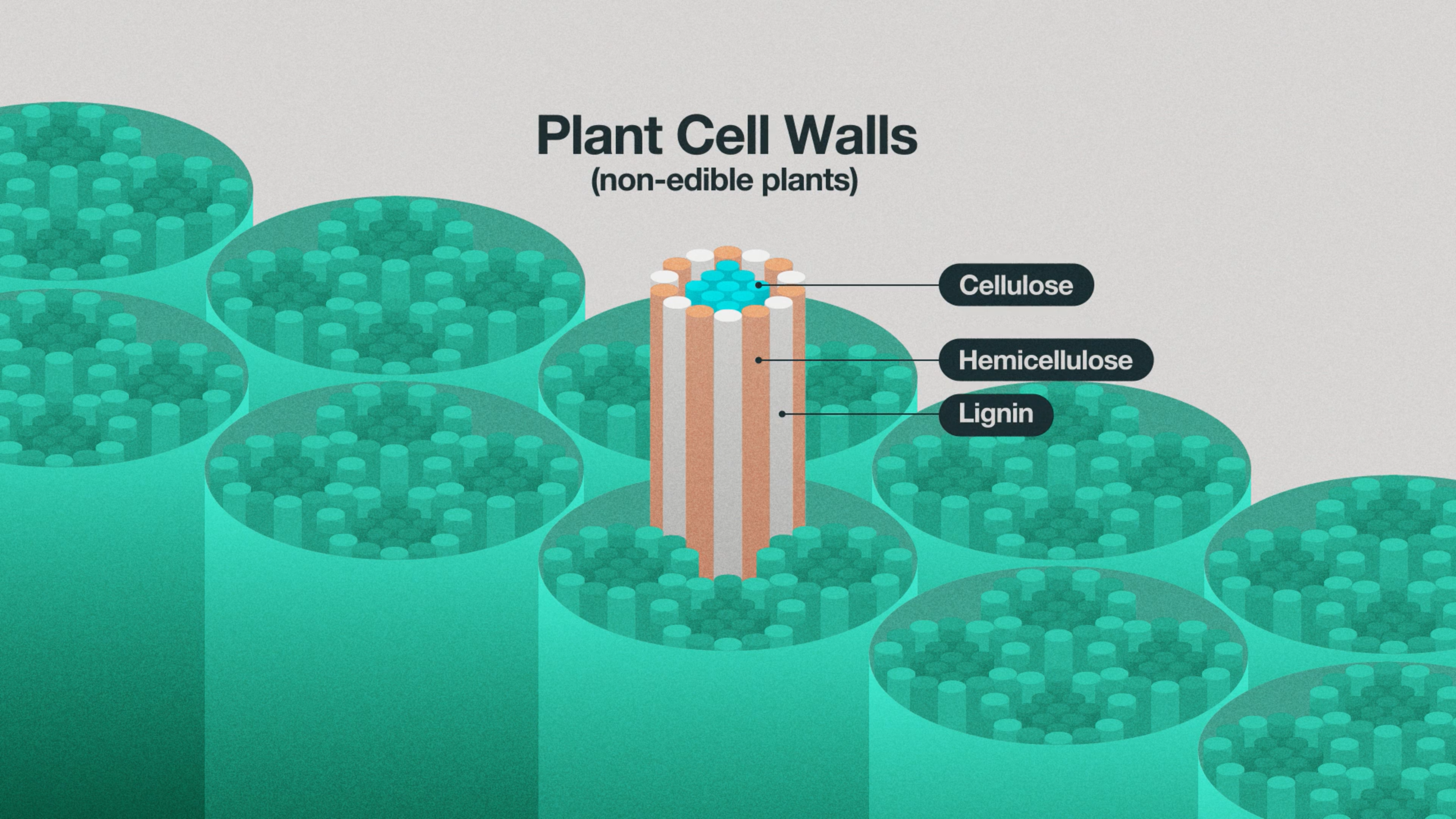

Before diving into what we know about feedstocks and their economic availability, let’s break down one of the processes used to create biofuels. Here in this diagram, we see that from nonedible plants, there are three components that make up this type of ligno-cellulosic plant matter: cellulose, hemicellulose, and lignin. These structures are what make a plant strong and durable. Once plant matter is grown and collected, it’s taken to a conversion facility where bio-reactors containing bacteria begin to break it down. Plants typically have varying degrees of recalcitrance, meaning how resistant they are to being metabolized by bacteria in the reactor. However, the bacteria used in these bioreactors have been specifically engineered in labs to recognize the polymers that make up plant cell walls and to be able to deconstruct them accordingly. Plant feedstocks, such as switchgrass and Poplar have also been engineered to have polymers that best suit the digestive microbes.

Once in the bioreactor, the bacteria first strip away, the lignin followed by the hemicellulose, until you get to the core of the cell wall, where the cellulose can then be broken down into sugars like glucose. The glucose is then fermented to produce ethanol vapors. These vapors are then passed through a catalyst that converts the ethanol into a hydrocarbon. This hybrid hydrocarbon has properties similar to diesel fuel, making it suitable to replace petroleum-based fuel. This process is well established and is how we get to commercially available ethanol used in vehicles today.

Matt Langholtz:

Biodiesel has made significant gains in recent years. Brazil powers a lot of their transportation with ethanol from sugarcane. Germany, and other countries power a lot of their vehicle fleet with biodiesel. So biofuels are here. In terms of what we’re talking about in this conversation, a main constraint is it’s hard to compete with $2 or $3 gasoline at the pump. Cellulosic ethanol is modeled to be, it’s probably looking at about $4 per gallon of gasoline equivalent.

When domestic supply of gasoline increases due to new technology like fracking, biofuels can be priced out. But with the advancement of feedstock production and technologies, biofuels have the potential to become much more competitive. Let’s take a look at some of these feedstocks, their availability and the cost of production. Feedstocks for biofuels are categorized into four generations. In this graphic, we see first-generation biofuels, which include bioethanol and biodiesel. These are produced from plants that are mostly edible, such as sugar cane and corn. Then we have second-generation biofuels, also known as advanced biofuels, which are manufactured from various types of non-edible biomass, such as lignocellulosic plants and waste. Among third generation biofuels, aquatic biomasses such as seaweed, kelp and algae are used as renewable sources. And lastly, we have fourth generation biofuels, which are made synthetically from cyanobacteria and algae.

FORESTS

When looking at forests and their feedstock potential, it’s important to take into account the fact that currently half of US forest land is considered timberland, meaning it’s ideal for forest products like pulp, paper and lumber. Therefore the competition is high for sustainable forest land.

Matt Langholtz:

After we exclude protected forests or sensitive forests and inaccessible forests, we find that at $60 a ton roadside there’s about 100 million tons per year of wood that could be derived from forest thinnings and logging residues. So those are forest thinnings, trees that are less than five or six inches diameter, and logging residues, tops and limbs that are left in the forest after trees are cut down. By the way, that’s less than 1% of the 15 to 20 billion tons of wood that’s standing on timberland. So it’s a tiny fraction of the total, it’s a significant potential cumulatively.

So where we lack in acquiring sustainable forest land dedicated to producing biofuels, we can turn to forest byproducts from other forestry operations. Economically, that’s about a 100 million tons of feedstock that could be added into our current bioenergy supply.

WASTE + AGRICULTURAL RESIDUES

But what about waste as fuel? What is considered good waste for biofuel production?

Matt Langholtz:

There’s urban wood waste. So that’s like power line trimmings and storm debris from urban areas. Municipal solid waste, which is basically your garbage. There’s secondary waste, which is mill processing residues, scraps from any kind of agricultural process, manures from confined animal feeding operations, industrial fat byproducts, or grease byproducts, or restaurant grease traps and things like this. A lot of it already used. All the fats, oils, and greases already goes a lot to biodiesel production. So the market works already where it can. In our billion ton report, we had about 100 million tons of forest land resources, that’s at $60 a ton roadside. On the wastes, if we also could afford about $60 a ton, we’d get another 100 million tons from this big mix of waste resources.

And that’s not all. Agricultural residues like corn stover, wheat straw, and other byproducts left on the fields can be used to supply another 100 million tons of biofuels. From these three feedstocks stocks alone, we see there’s enormous amounts of material that are just sitting there waiting to be used. What’s currently lacking in making this a reality is the support of public policy, an adequate price on carbon, and sufficient investment from public and private sectors. If these hurdles can be overcome, biofuels have a strong potential to displace global dependence on fossil fuels.

ALGAE

And this doesn’t take into account the potential of algae feedstock. One of the most important things to note about algae is that it requires no agricultural land. So there’s no conflict between food and fuel. However, it does require new infrastructure to be built, which can be expensive. In regards to CO2 sequestration, algae is a powerful tool that can be used near CO2 emitting facilities, such as coal, natural gas and electricity generation plants in order to offset emissions.

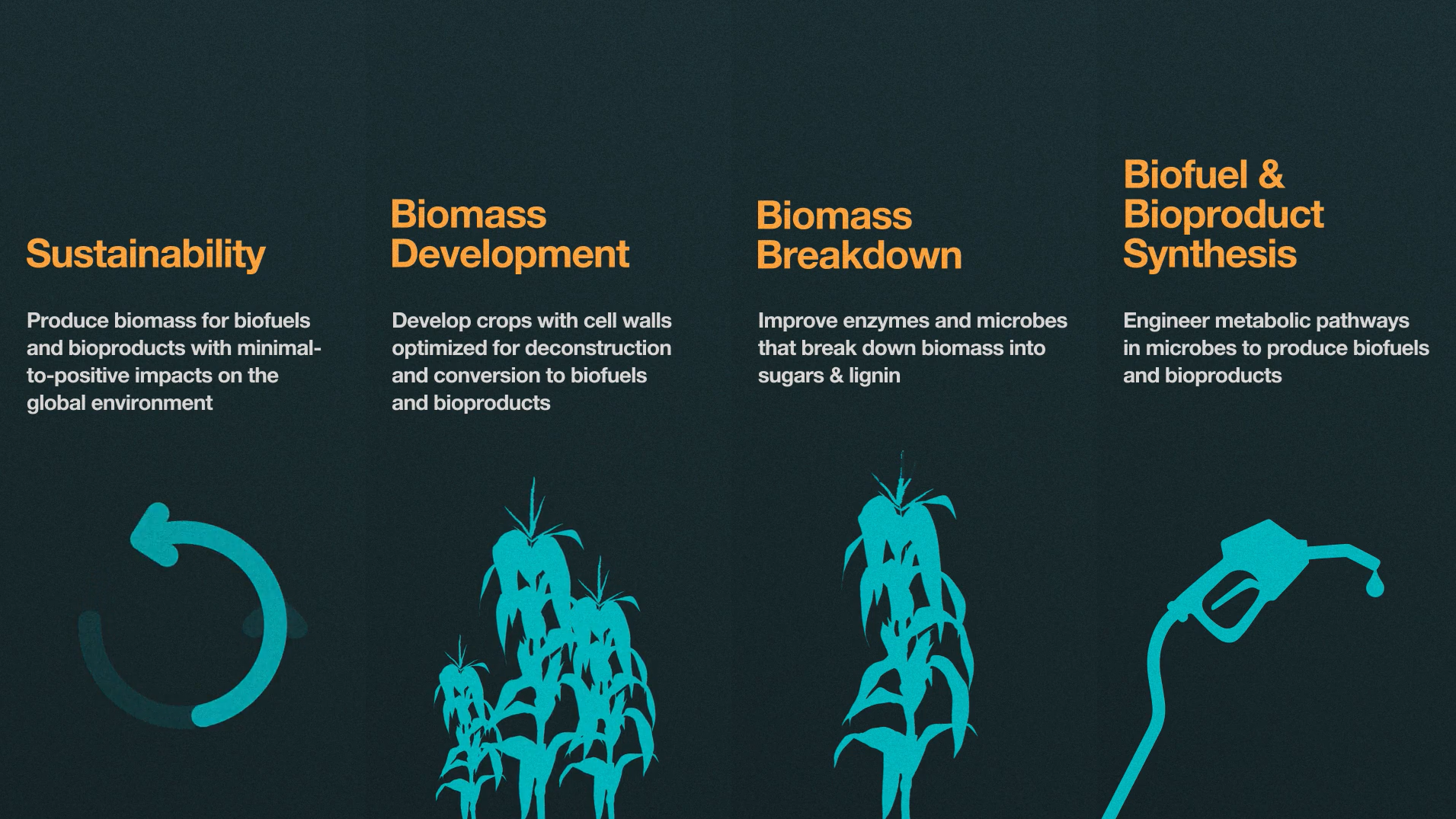

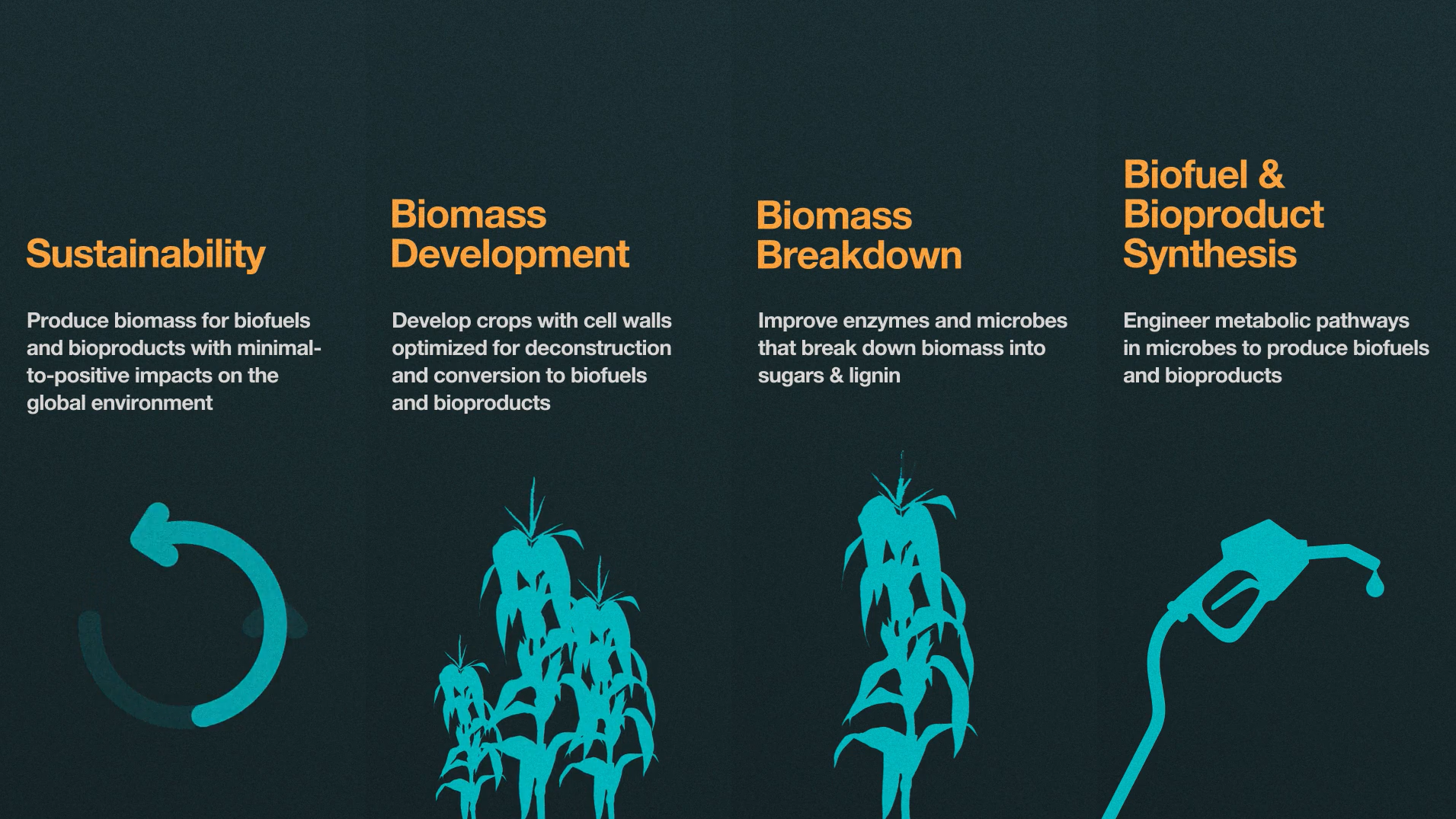

According to the Department of Energy’s Bioenergy Research Centers 2020 update, advancements in each phase of the biofuel production line will help to spur future growth in the bioenergy sector and lower overall costs from improving methods to sustainably sourcing biomass feedstock, to genetically engineering plants and bacteria to improve deconstruction of plant matter, to the final conversion of biofuels, biofuels stand a chance to eliminate global dependence on petroleum.

For a deeper dive into this topic, check out our full length podcast with Jerry Tuscan and Matt Langholtz, where we went into detail about biofuel technology and its role in decarbonizing the economy, or check out our newsletter. For more video and podcast episodes, to sign up for our new releases and more, visit climatenow.com.

Sources

0:12 – IEA Bioenergy Annual Report 2020. (2021, April). https://www.ieabioenergy.com/wp-content/uploads/2021/04/IEAB-Annual-Report-2020.pdf also here https://www.iea.org/data-and-statistics/charts/world-total-energy-supply-by-source-1971-2018

2:00 – Fossil vs biogenic CO2 emissions (2021). IEA Bioenergy. https://www.ieabioenergy.com/iea-publications/faq/woodybiomass/biogenic-co2/

2:24 – Field, J. L., Richard, T. L., Smithwick, E. A. H., Cai, H., Laser, M. S., LeBauer, D. S., … Lynd, L. R. (2020, September 8). Robust paths to net greenhouse gas mitigation and negative emissions via advanced biofuels. PNAS. https://www.pnas.org/content/117/36/21968

2:45 – Luterbacher C and Luterbacher J (2015) Break it Down! How Scientists are Making Fuel Out of Plants. Front. Young Minds. 3:10. doi: 10.3389/frym.2015.00010

3:12 – Holwerda, E.K., Worthen, R.S., Kothari, N. et al. Multiple levers for overcoming the recalcitrance of lignocellulosic biomass. Biotechnol Biofuels 12, 15 (2019). https://doi.org/10.1186/s13068-019-1353-7

4:52 – Javed, M. R., Bilal, M. J., Mehmood, M. A., Ashraf, M. U. F., Waqar, A., Saeed, M., & Nashat, N. (2019, December). Microalgae as a Feedstock for Biofuel Production: Current Status and Future Prospects. ResearchGate. https://www.researchgate.net/publication/337925810_Microalgae_as_a_Feedstock_for_Biofuel_Production_Current_Status_and_Future_Prospects

5:35 Forest Ownership Statistics. National Association of State Foresters. (2020, February 12). https://www.stateforesters.org/timber-assurance/legality/forest-ownership-statistics/

6:00 – U.S. Department of Energy. 2016. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy, Volume 1: Economic Availability of Feedstocks. M. H. Langholtz, B. J. Stokes, and L. M. Eaton (Leads), ORNL/TM-2016/160. Oak Ridge National Laboratory, Oak Ridge, TN. 448p. doi: 10.2172/1271651. http://energy.gov/eere/bioenergy/2016-billion-ton-report.

7:42 – U.S. Department of Energy. 2016. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy, Volume 1: Economic Availability of Feedstocks. M. H. Langholtz, B. J. Stokes, and L. M. Eaton (Leads), ORNL/TM-2016/160. Oak Ridge National Laboratory, Oak Ridge, TN. 448p. doi: 10.2172/1271651. http://energy.gov/eere/bioenergy/2016-billion-ton-report.

9:00 – U.S. DOE. 2020. U.S. Department of Energy Bioenergy Research Centers: 2020 Program Update, DOE/SC–0201. U.S. Department of Energy Office of Science genomicscience.energy.gov/centers/BRC2020programupdate.pdf